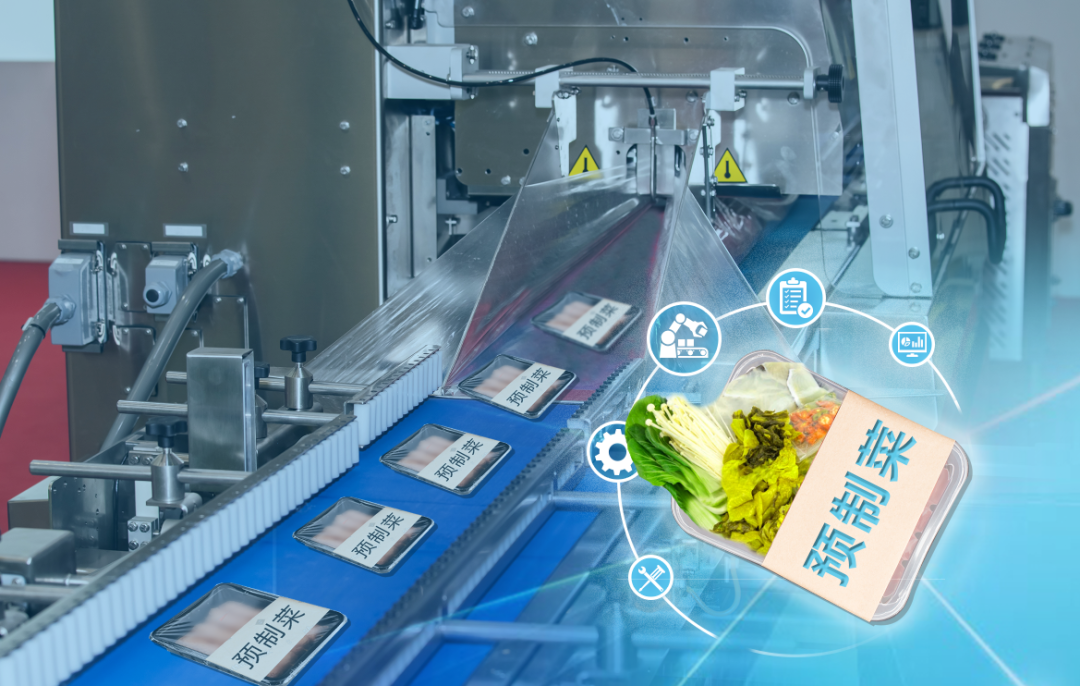

The development and application of industrialization has significantly improved the efficiency and quality of modern life. The popularity of “pre-prepared dishes” is a major example. Using industrial-grade standardized operating procedures, the ingredients of dishes are made into semi-finished products for standby use, which greatly reduces the time and effort of daily cooking.

The huge market size and prospects have also attracted many food processing companies to invest. The packaging link is directly related to the hygiene and safety of dishes and the efficiency of processing and transportation.

Delta’s packaging solution is efficient, flexible, and intelligent, injecting new momentum into the production of pre-prepared dishes.

Momentum 1: Helping pillow packaging machines to complete high-quality bag sealing

In the production of pre-prepared food, the final finished product needs to be individually packaged to ensure fresh quality during transportation and delivery to users; the most commonly used are multi-scale and continuous pillow packaging machines.

Delta’s pillow packaging machine solution has higher levels of controllability, stability, and precision. It can switch between fixed-length mode and color code mode at will, and has precise temperature control, which is perfectly qualified for multi-task processing needs.

Dynamic force 2: Assisting vertical packaging machines to flexibly achieve three-side sealing

Vertical packaging machines are often used for packaging of pre-prepared food such as granules, short strips, and vermicelli. The packaging machine makes the packaging plastic film into a cylinder, puts the pre-prepared food into it, and seals the side with a heat longitudinal sealing device.

Delta’s solution has strong multi-axis control capabilities, and can modify the bag length in real time during equipment operation, flexibly adapting to various production methods, allowing the packaging machine to achieve 40-150mm bag length processing.

Dynamic force 3: Integrated packaging optimizes the performance of horizontal packaging machines

Horizontal packaging machines can make targeted adjustments to the packaging bag type according to the different materials, and realize the full process packaging process from fully automatic bag making, filling to sealing. They are mostly used for packaging of liquid and powdered pre-prepared food items.

Delta’s solution starts with the personalized needs of process station control, and performs modular program design corresponding to different processes, which significantly improves the speed of the packaging machine, optimizes control needs, and makes operation more convenient.

Dynamic force 4: further promote the evolution and upgrade of the whole process of bag-feeding packaging machine

The application range of bag-feeding packaging machine is extremely wide. It can be used for a variety of packaging materials such as paper plastic, aluminum plastic, PE composite, etc., with good sealing quality. In the production of pre-prepared dishes, it is often used for high-end packaging of granular, block, liquid and other dishes.

Delta’s solution has a high degree of system integration, perfectly assisting the bag-feeding packaging machine to complete the whole process of automation from bagging, printing to bag opening, filling, heat sealing, shaping and outputting finished products. The solution is easy to connect and flexible to expand.

Dynamic force five: driving the automatic packaging material sorting line to greatly improve efficiency

The material sorting line can sort and automatically distribute the processed pre-prepared dishes, and send the finished products to the packaging machine in an orderly, smooth and non-damaged manner. It has high requirements for stability and speed in transportation and distribution, and can achieve start and stop of materials without slipping at high speed, and the material fork is accurately matched without omission or overlap.

Relying on the powerful driving and control capabilities of Delta’s industrial automation products, this solution allows the material sorting line to operate stably and reliably, control the feeding smoothly and accurately, improve operating efficiency and significantly reduce invalid losses.

As the public pays more and more attention to the health, greenness and nutrition of food, starting from the packaging of production and transportation, improving the freshness of goods is also the responsibility and development direction of the food packaging industry.

With its profound industrial automation technology and industry knowledge, Delta customizes flexible, reliable and stable solutions for the food and beverage industry, and continues to create higher advantage value for customers!

Related product recommendations:

EPRO PR6424/006-010

Honeywell FC-TPSU-2430

Siemens 6ES7531-7QD00-0AB0

ABB PP875 3BSE092977R1

Honeywell MU-PPIX02

GE Multilin Relays 745-W3-P511-G51-HI-R-E-H

Mean Well PSP-600-24

GE UR8LH

Bently Nevada 330103-00-11-10-02-CN

ABB SC300E-MPP

GE IC693PWR321

Siemens 6SE7021-6ES87-2DA1

Schneider Electric 140CPS21400

Indramat TVM1.2-050-220/300-W0

Honeywell SPS5710 51198685-100

SIEMENS 6EP1 332-2BA10

Rexroth R911284231 – CCD01.1-KE19-01-FW

GE IS220PPROH1A

ABB CI810A 3BSE013262R1

HIMA F3105

SIEMENS 6SX7010-0KC00/6SE7090-0XX84-0KC0

ABB SACE PR122/P-LSIG

SIEMENS 6GK5008-0BA00

Phoenix IBS S5 100 CB-T, P/N: 2753698

SIEMENS Simatic S5 951

GE DS200SHVIG1BGD

Honeywell 51304437-150

Siemens 6DM1001-0WB00-2/E89110-F1391-C3-E

SIEMENS SIMATIC S7-300 6ES7368-3BB01-0AA0

Honeywell HC900 900U02-0100

GE UR6EH

ABB YXU169B0

More……

Leave a comment

Your email address will not be published. Required fields are marked *